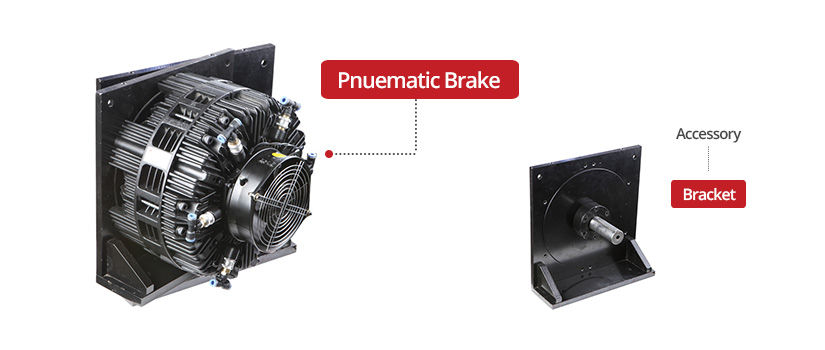

Pnuematic Brake is introduced by Puretronics for maintaing the tension of the product during the production. Manufacuring this types of brakes for more than 10 Years, Puretronics is one of leaders of manufacuring Pnuematic Brakes in India.

Pneumatic Brake

Elevate your braking performance with Puretronics' Pneumatic Brake Systems. Our advanced technology ensures precise and reliable braking in various applications. Trust Puretronics for high-performance pneumatic brakes designed to enhance control and safety. Upgrade your braking systems with Puretronics and experience superior efficiency and durability in pneumatic braking.

-

Features

-

Technical Specification

-

Accessory

-

Application

- Compact size gives more compact machine design

- Easy disassembly of brake design, results into easy maintenance

- Easy disassembly of brake design, results into easy maintenance

- Design of brake housing gives us efficient heat dissipation

- Electrical fan fitted on center hole to ensure constant heat dissipation

- Bi-directional turbine and surrounding housing with ventilation hole permitting air circulation from middle to periphery of unit results best thermal power dissipation

- Constant controllable torque due to stable friction lining material

Advantages :

- Bidirectional turbine on the braking element.

- Special hole pattern on the housing to enhance the ventilation & air cooling.

- Additional electric fan further enhances the thermal power dissipation.

- Maximum heat transfer.

- High quality friction pads ensure a constant controllable torque.

- Highly reliable design.

- Modular design for wide range selection.

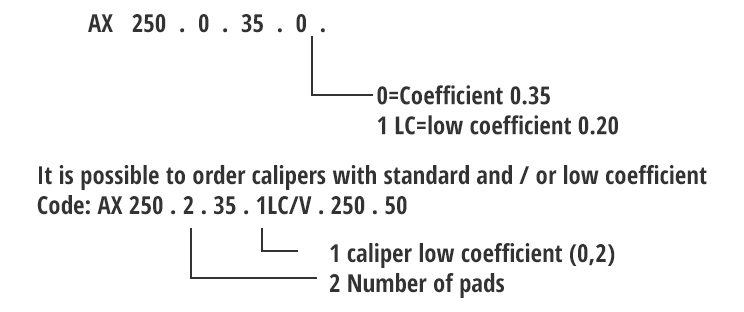

Selection Code :

| Friction Coeff | Min 0.2 atm | Max 6 atm | Friction Coeff. | Min 0.2 atm | Max 6 atm | |

|---|---|---|---|---|---|---|

| Standard | 0.15 | 16 | Min / Rpm | 100 | 300 | 1000 |

| Low Coeff. | 0.075 | 5 | With Fan | 3:5 | 4.4 | 8.9 |

| Max Rpm | Weight | Inertia | ||||

| 2500 | ~22 Kg | i=0.058 kgm |

| MOUNTING-BRACKET-AX-250 | The mounting bracket enables the user to mount the pnuematic brake onto the machine. Widely used to ease the hurdles of the user to make arrangements for its mounting and can be used for modification jobs as well. |

|

|---|

- Printing

- Wires

- Plastic

- Paper Industries

- Metal

- Packaging

- Textiles

- Web Processing