Sterlite Industries is one of the leading producers and suppliers of customized cable solutions to cater to high-bandwidth applications of data centers, global internet companies, ISPs and telcos, citizen network services.

D2 chamber for making fiber optic spool for Sterlite

Overview

Sterlite Industries required a chamber system to prepare the fiber optic spool from Deuterium and Nitrogen gas and all the necessary settings and equipment along with it. The setup is required for quality production of its fine width optical fiber which will be applicable for various functionalities

Solution

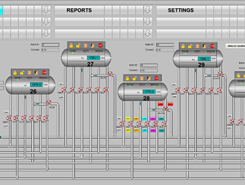

- The design was drafted in such a way that the whole process of mixing the gases in an appropriate proportion will be automatically controlled through PLC.

- The Mechanical assembly and Electrical control panel setup were designed in collaboration with our associates.

- Recipe manual setup provided in order to make the spool better in accordance with the QC department.

- Provided report generation in order to keep track of the live data and historical data.

Value addition

- To compensate for the loss due to leakage we developed a Dead Band so that the pressure can be adjusted through pneumatic valves.

- We modified the time interval of report generation from 1 hr to 1 Min interval, so as to provide and help analyze real-time data more accurately.

- We added a safety alarm to the system. The system was modified in a manner that an alarm will ring while opening and closing chamber doors.

- Programming interlocks were given for Opening and closing of the door during the air pressure or vacuum presence.

Exhibits