Aluminium foils find a wide range of applications in packaging products like tea, coffee, chocolates, confectionery, medical tablets, tobacco, etc. PG Foils exports its products to Bangladesh, Thailand and Nepal. In the domestic market, the company's customers include all the leading companies in the pharmaceutical industry such as Hoechst (India), Glaxo, Pfizer, the Cadila group, Nicholas Piramal, Panjon, the Torrent group, etc. Besides, the company caters to the Sivakasi market which consumes 30-40 tpa of paper laminated foil for packing fireworks. It also supplies casserole foil to the Indian Railways and pharma foils to IDPL under an annual contract.

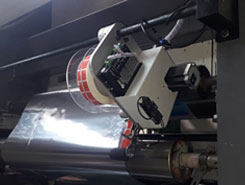

Labeller for detecting and marking defects for PG Foils

Overview

PG Foils was facing the issue of irregularities and defects in their aluminium foils they were manufacturing and as they the processing speed of the rollers were too high it was very difficult for them to make the irregularities while production on the foils. These irregularities were impacting the final product and hence impacting their credibility as they have global customers.

Solution

- We came up with a solution to provide them with a Labeller for detecting and marking defects for PG Foils along with a Vision Inspection System.

- The Vision Inspection System inspects the running foils during production and sends a signal to the labeller whenever it finds any discrepancy in the foil. The labeller then labels the foil at the exact location

- The coordination is controlled by a PLC and helps synchronise the activities

- We also modified the system by adding a bracket to support the labeller movement

Value addition

- The assemble helped remove manual intervention for quality assurance and save manpower.

- The system improved the accuracy with which the defects were detected and which could have possibly missed by naked eyes.

- Automated the whole process which improved quality assurance and performance

Exhibits